Some knowledge points about diamond grinding wheels

Category: Industry News

Sep 27,2021

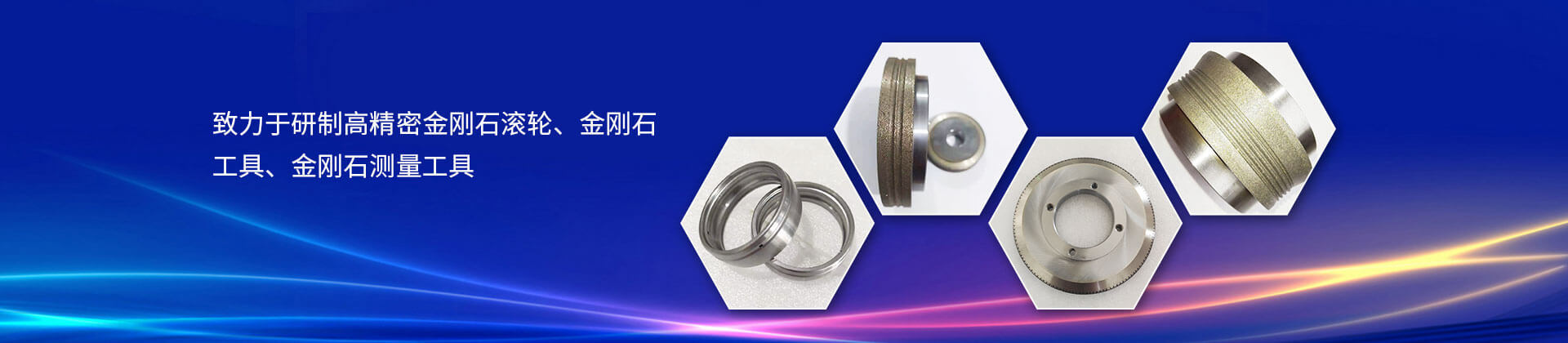

The structure and shape of diamond rollers are diverse, with various styles and odd shapes. Different industries have different types, and even within the same industry, there are many varieties. The shape of the roller is determined by the circumferential shape of the grinding wheel or the circumferential shape of the grinding wheel group. This is why it is said that the application of rollers is in mechanical processing grinding machines for shaping and grinding, which basically belongs to a later process.

Unlike diamond pens or SBD powder dressing pens, they reciprocate to dress parallel grinding wheels.

No matter how complex the profile is, generally speaking, the structure of the roller can be divided into three parts: diamond layer, steel core, and inner hole. This is also why several key elements on the Shili diamond roller inquiry table correspond to these three major parts of roller structure.

Whether it is electroplated or sintered rollers, the working layer is always the diamond layer. The abrasive on the inquiry table corresponds to selecting appropriate diamond particle abrasives. For the shape and size of the grinding wheel, we can design a corresponding steel core. The steel core serves as a support for the diamond layer and corresponds to the outer diameter size of the roller. The inner hole refers to its inner diameter, which corresponds to the spindle of the roller installation device that requires high precision. The precision level of the inner hole corresponds to that of the dressed grinding wheel, ultimately affecting workpieces; therefore, tolerance requirements for inner holes are also strict.

By analyzing the structure of rollers, it can be concluded that their price is mainly determined by the diamond layer plus precision requirements.

The amount of diamond particles in terms of carats, profile size precision, roughness, tolerance requirements for inner hole precision, contour accuracy etc., determine how difficult it is to manufacture during dressing processes. The more complex it is, the harder it becomes; thus labor costs increase as labor is quite expensive now. Therefore, prices tend to be slightly higher.

Related Articles

Aug 16,2021

Mar 18,2022

Aug 16,2021

Aug 16,2021

Aug 27,2021

Aug 27,2021