Structure design of diamond dressers

Category: Industry News

Sep 18,2021

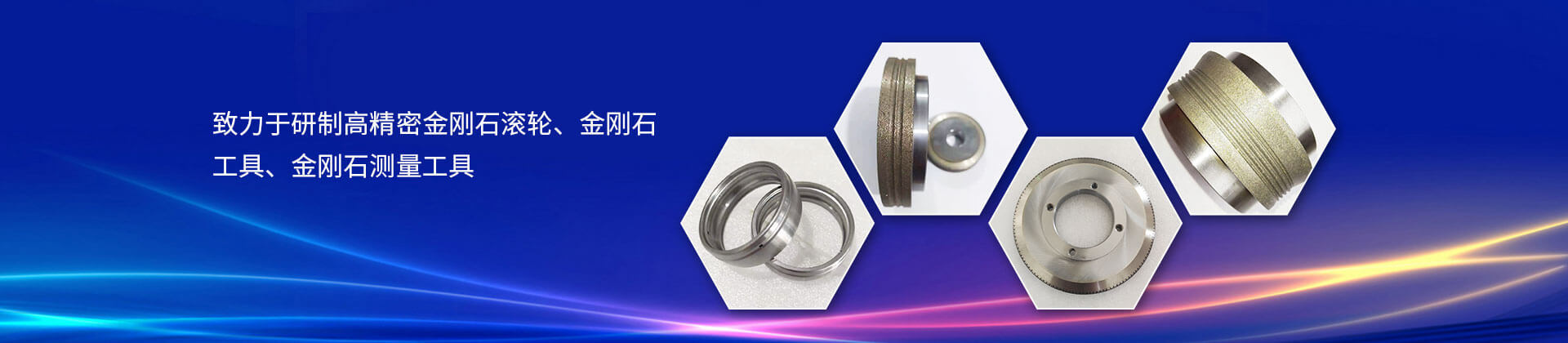

When processing shaft workpieces, there are often difficulties in machining various arcs with high dimensional accuracy and low surface roughness values. Diamond dressers are often used to shape grind arcs and design shaping grinding wheels for arc processing.Diamond dresser.

Form grinding involves dressing the grinding wheel to match the profile of the workpiece, ensuring complete contact between the wheel and the workpiece during processing, thus replicating the wheel's profile. It is a high-precision, low-cost finishing method. Due to different peripheral speeds at various points on the wheel, material removal rates vary, leading to uneven wear of the wheel, especially at sharp points which are prone to breakage, resulting in shape errors. The formed shape of parts is a replica of a four-wheel shape, which affects machining accuracy. If the grinding allowance is uneven, defects such as grinding burns may occur; therefore, trimming of the forming four wheels has a decisive impact on the form grinding process. A specialized diamond dresser has been designed for shaping wheels used in arc processing.

Diamond dresser spindle component

This part is the core component of the dressing device. The diamond roller is mounted on it, and its precision directly affects trimming accuracy and thus impacts workpiece precision. Ensuring this device's precision involves core technologies in methods, design, processing, and assembly. Additionally, the diamond wheel spindle must have sufficient rigidity. Considering that diamond wheel trimming exerts considerable force, to enhance wheel life, its diameter should be as large as possible. In this design, a wheel diameter of 140mm was chosen. The spindle for diamond edge trimming uses a structure shown in Figure 1. This structure is simple; machining precision is easy to guarantee; adjustments are relatively convenient; it has high precision with radial runout less than 0.003mm, axial runout less than 0.003mm, and end runout less than 0.003mm.

Diamond dresser motor power

Diamond roller trimming is formed using grinding methods while diamond pen trimming uses lathe processing methods; hence the former requires greater preparation force than the latter necessitating sufficient torque from the motor. The power calculation for trimming motors is between 15 to 30 watts per millimeter width; thus a larger motor power of about 1KW is used due to specific structural requirements and wider processed components (65mm), leading to a selection of motor power at 1.5 kilowatts.

Diamond dresser electric components

The role of electric components is to ensure that the rotational speed of the diamond grinding wheel meets requirements during trimming processes while smoothly transmitting rotational motion from the motor to the spindle.

Diamond dresser conveying components

The function of conveying components is to achieve accurate entry into operations with feed speeds lower than each diamond wheel's feed speed by up to 0.2m for quick tool withdrawal allowing control over light repair rotations during wheel trimming.

Diamond dresser connection components

The role of connection components is to facilitate connections with grinders where different types should have distinct structural designs for connection parts. For semi-automatic external cylindrical grinders, installation space and position require mounting dressing devices behind wheels connected via sliders and guide rails.

In past processes, four-wheel rounding was entirely done manually using diamond tools on four wheels requiring formal processing only after examination leading to low productivity and difficulty in ensuring accuracy while placing high technical demands on operators.Diamond dresserUsing shaping wheels for processing ensures both accuracy and productivity with excellent results.

Related Articles

Aug 16,2021

Mar 18,2022

Aug 16,2021

Aug 16,2021

Aug 27,2021

Aug 27,2021