Product classification

CVD diamond grinding wheel

Classification:

Product Center

Diamond grinding wheel

Diamond tools

E-mail:hndongjin@126.com

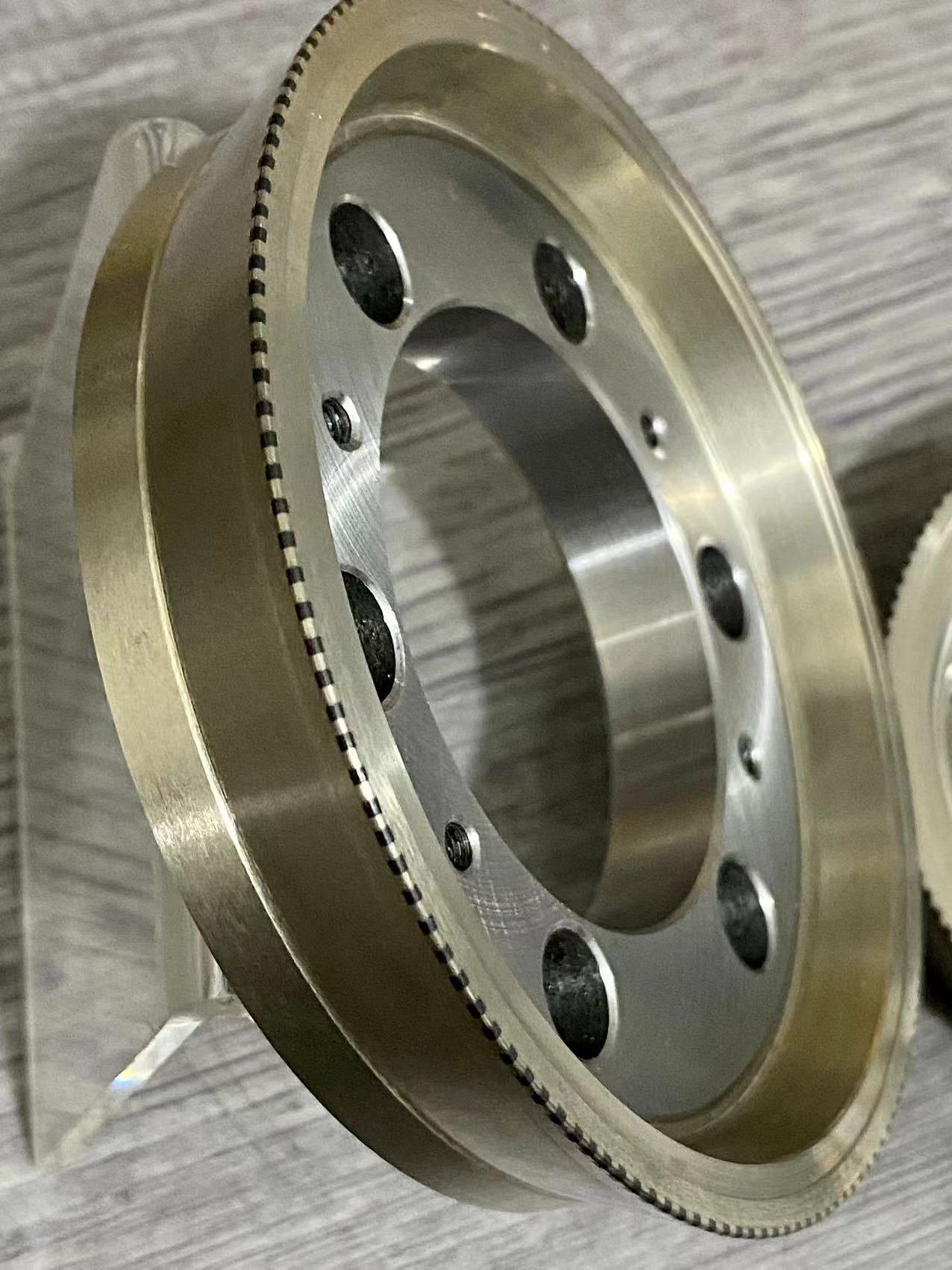

CVD diamond grinding wheel

Processing of precious metals and their high-precision parts in the manufacturing industry of mechanical machine tools and grinding machines

For example, aerospace blades, inner grooves of bearings, gears, guide rails, and taps require high precision and surface finish. Therefore, diamond dressing tools—grinding wheels have been used for a long time to meet these requirements.

With high precision requirements and relatively high roughness requirements, grinding processing is used. The grinding wheel can be well shaped and sharpened during the forming grinding process, equivalent to a tool. Diamond has extremely high hardness and excellent thermal conductivity characteristics, so it has irreplaceable advantages among dressing tool materials. According to different types of diamonds, diamond cutting tools are divided into single crystal diamond dressing pens, polycrystalline diamond grinding wheels, and chemical vapor deposition (CVD) diamond grinding wheels. CVD diamond grinding wheels have higher strength and better wear resistance; they often appear at the tips of the wheels for reinforcement and orderly arrangement.

CVD diamonds are very sharp and hard; they are not only used in diamond grinding wheels but also in some precious metal superhard materials that directly use CVD diamond film cutting tools for cutting.

Key words:

Diamond tools

Diamond grinding wheel

Previous:

Next:

Related Products

Leave us a message

We always uphold the business philosophy of win-win cooperation, look forward to working with you hand in hand, mutual benefit and win-win, create brilliant!