Product classification

Diamond grinding wheels in the bearing industry

Classification:

Diamond grinding wheel

E-mail:hndongjin@126.com

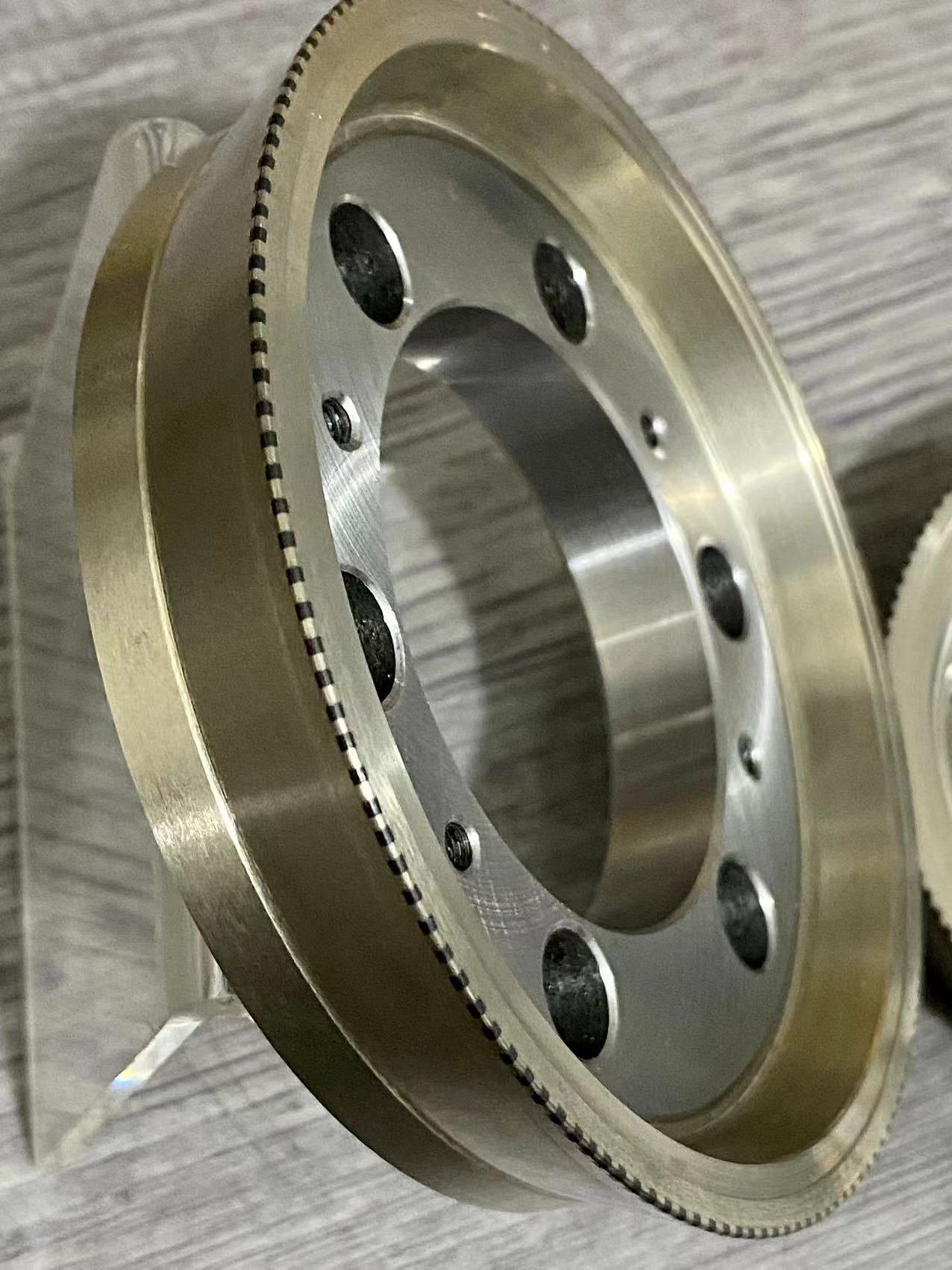

Diamond rollers, also known as diamond dressing rollers or diamond roller dressers, are grinding wheel dressing tools used for mass-forming grinding. They can replace single crystal diamond pens for dressing grinding wheels, significantly improving production efficiency and achieving higher surface quality and precision of the processed parts.

Application industries of diamond rollers

Diamond rollers can be used in various industries such as automotive, aerospace, measuring tools, machine tools, etc. Typical applications include gears, bearings, crankshafts, lead screws, ball cages, blades, oil nozzle pumps, measuring tools, guide rail blocks, micro rails, calipers, etc. In other words, wherever there is a demand for high-volume, high-efficiency precision dressing of grinding wheels, diamond rollers can be utilized. When paired with CNC machine tools and gear grinding machines, they require less manual experience and have significant advantages over diamond pens.

Key points to note when using diamond rollers

As the number of hard and difficult-to-grind materials in the machinery industry increases today, the frequency of using diamond rollers to dress grinding wheels is also rising. Among current abrasives, diamonds have high hardness and are not easily worn out; however, they are not particularly heat-resistant. To use diamond rollers effectively and reasonably, pay attention to the following points:

1. Main parameters such as peripheral speed during dressing of grinding wheels with diamond rollers; left-right feed amount; front-back feed amount.

2. Feed amount and grinding pressure during diamond roller grinding; issues like deflection or misalignment of the diamond roller.

3. Follow the action sequence when dressing a grinding wheel with a diamond roller: fast approach (do not touch the wheel) → slow approach (feed at required cutting speed) → light dress → withdrawal; do not skip steps as it will affect the lifespan of the diamond roller.

Product Description

The working principle of a diamond roller is: by installing it on a dressing device on a grinder machine to dress ordinary ceramic or CBN wheels. After shaping the wheel, parts are ground so that the contour profile and precision dimensions of the diamond roller are copied onto the surface of the processed parts through the wheel. Its characteristics include simple operation for machine tools with low technical requirements for operators; good consistency in product precision; stable quality; significant improvements in production efficiency and product quality; reduced manufacturing costs; and easy automation of grinding processes. Compared to traditional single-point diamond pen dressing methods, production efficiency is greatly improved while achieving higher surface quality and precision in processed parts—especially suitable for high-precision mass production.

Product Advantages

We have rich engineering design and manufacturing capabilities focused on developing better forming diamond rollers to provide long-term technical support for our customers and maintain stability in their mass production.

With our research and development capabilities for diamond rollers along with high-precision processing capabilities, our company has become a supplier replacing imported products for high-end clients—East Precision Engineering excels at craftsmanship.

Target Audience

Products are mainly applied in manufacturing various automotive components across different bearing industries; textile machinery gears; petroleum machinery; cylinder heads; pistons; piston rings; bearing shells; electric vehicles; sewing machines; power tools; measuring tool industries; aerospace industry; abrasive mold industry; precision lead screw guide rails among others for mass-forming processing and non-ferrous metal finishing enterprises.

Patented Products

|

|

|

|

|

Cage bell-shaped shell spherical roller |

Single groove lock clamp groove roller |

Multi-groove lock clamp groove roller |

Slider diamond roller |

|

|

|

|

|

Valve cone sealing surface roller |

CNC single-line grinding tap diamond roller |

'Tap forming grind' roller |

'Bell-shaped shell channel grind' diamond roller |

Patent Certificate

Key words:

Diamond grinding wheel

Related Products

Leave us a message

We always uphold the business philosophy of win-win cooperation, look forward to working with you hand in hand, mutual benefit and win-win, create brilliant!